The laboratory was equipped with two types of thin film and coating equipment:

- Atomic Layer Deposition (ALD)

- Physical Vapour Deposition (PVD)

Atomic Layer Deposition (ALD)

Physical Vapour Deposition (PVD)

Atomic Layer Deposition (ALD)

Beneq TFS200 – Single atomic layer deposition system

- the device allows thin layers to be created at temperatures of up to 500°C

- the process takes place in a nitrogen atmosphere 5.0

- internal dimensions of the chamber: diameter 200mm, height 90mm

- we have a wide range of precursors, such as: zinc, tin, aluminium, titanium, zirconium, tantalum

- the layer can consist of either one of the precursors, several, or their oxides

- it is possible to control both the quantity and duration of individual cycles

Beneq TFS200 parameters:

- 2 chambers 200 mm x 95 mm

- 1 chamber 200 mm x 18 mm

- 4 liquid sources

- 2 heated sources

- 2 gas lines

- O3 delivery system

- Nanoparticle coating module

- Excellent adhesion – chemisorption

- Sequentiality

- Repeatability,

- High throughput,

- Low process temperature,

- Controlled thickness

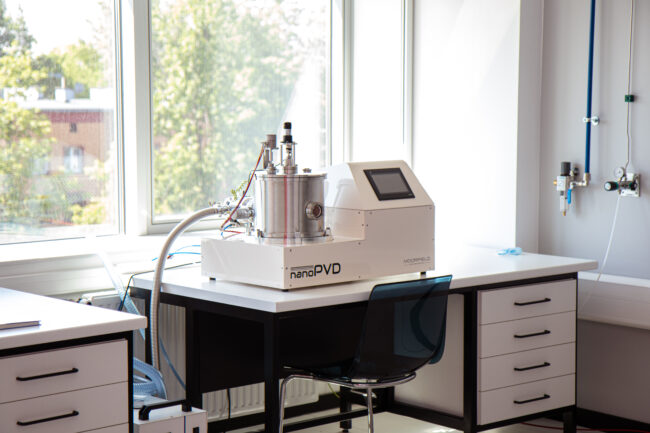

Physical Vapour Deposition (PVD)

Physical Vapour Deposition (PVD) system equipped with a magnetron sputtering module.

- The base pressure in the chamber is 5×10-7 mbar – UHV (Ultra High Vacuum) standard.

- Possibility to install up to 3 magnetron guns and two types of DC and RF power supply, together with a co-deposition module and gas lines for nitrogen and oxygen.

- Chamber, showing magnetron sputtering source in operation

Moorfield’s device, the nanoPVD-S10A, is a magnetron sputtering system for sputtering metals or insulating materials such as oxides and nitrides. The units are equipped with turbomolecular pumping systems to ensure low contamination operation. Co-deposition is possible, as well as reactive sputtering using a gas/pressure control module that can handle up to three process gases. The system works with classic industrial targets (e.g. TiN, TiO2, C) and substrates up to 4″ in size.