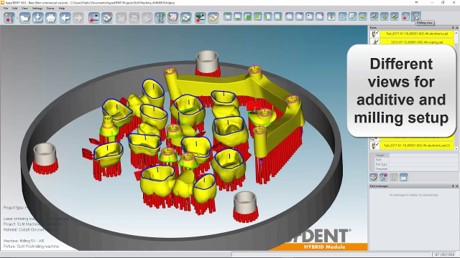

RS5 magnetic milling machine with CAM software

- 3 + 2 milling including such materials as: zircon, titanium, CoCr

- intended, among others for the manufacture of prosthetic products such as: implants, acrylic dentures, surgical templates and products made of glass ceramics with trochoidal processing

- software containing a package of implant geometry and implant connectors

SD Mechatronik THE-1100 Thermocycler

A thermocycler equipped with an open preparation basket that is alternately immersed in a bath of hot and cold liquid to ensure a high rate of temperature change (to realistically simulate temperature changes in the oral cavity), thereby simulating the artificial ageing process of materials used for prosthetic restorations.

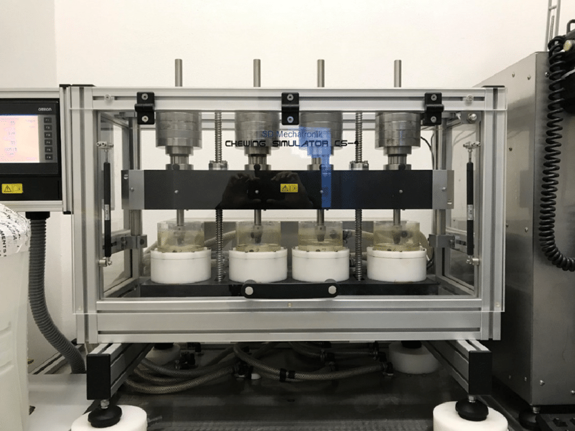

SD Mechatronik CS-4 chewing movements simulator

The device simulates various chewing movements in the mouth to evaluate materials used for implants, bridges, crowns, composite materials and jaw models:

- execution of complete chewing cycles using linear 2-axis movement

- circular 2-axis movement for higher simulation frequencies up to 5Hz

- simulation of bruxism, in particular for the testing of bite splints