Station for the determination of mechanical properties of materials and structures

MTS Bionix tabletop test system

The dynamic test system enables accurate, reproducible testing of fatigue life, fracture mechanics, tension, bending, torsion and compression of various materials. The axial-torsional system enables cyclic tests to be carried out to simulate the operation of a medical device under actual loading conditions. The proposed tests make it possible to assess the device in terms of its durability and wear.

parameters:

- 0-25 kN for axial force

- Force display accuracy 1 N

- 250 Nm for torsion torque

- Accuracy of torque indication 0.5 Nm

We conduct the following tests:

- durability tests

- wear tests

- determination of fatigue curves,

- tests on standardised samples,

- tests on non-standardised samples,

- of complete structural assemblies.

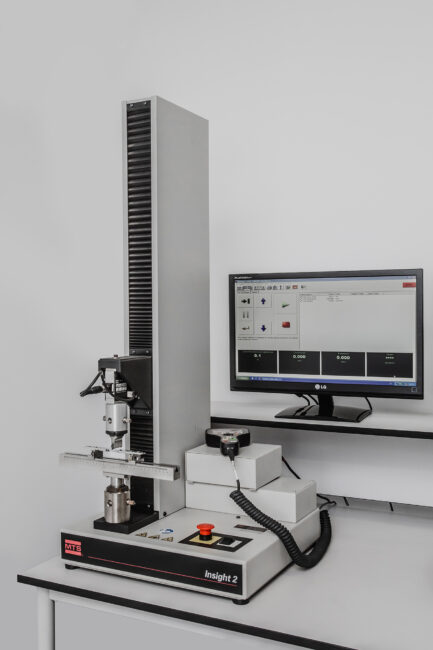

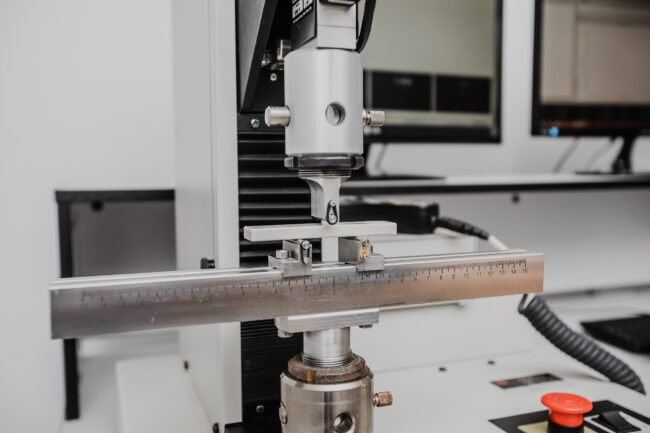

MTS Insight 2 universal test system

Testing machine for static tensile, compression and bending tests with computer recording of force and elongation measurements.

We carry out tests according to the test standards specified by the customer or based on individual customer requests. We design the test path for non-standard requirements.

Parameters:

- 0-2 kN measuring range

- Accuracy of force indication 0.01 N

- diameter dimensions for round specimens 3-12.7 mm

- maximum dimensions for flat specimens :

Width: 25mm | Thickness: 13.2mm | Length: 400mm

We conduct the tests on:

- plastics

- textiles

- rubbers

- wires

- ropes

ME – 46 video extensometer

It is a system that enables a non-contact measurement of a specimen.

Thanks to the very high resolution of the recorded image, it enables the properties of materials to be traced at very low strains.

The system is highly accurate, versatile and is ideal for non-contact strain measurements. The video-extensometer acts as a strain gauge by continuously measuring the distance between marked markers. Strain is calculated by measuring the distance between markers relative to the initial distance.

The minimum resolution achieved during measurements depends on the size of the measuring field.

Axis length of the study area | Minimum resolution [µm] |

|---|---|

| 50 | < 0.3 |

| 250 | < 1.5 |

| 500 | < 3 |

| 1000 | < 6 |

We conduct tests on:

- biological tissues

- plastics

- metals

- textiles

- rubbers

- wires

- ropes

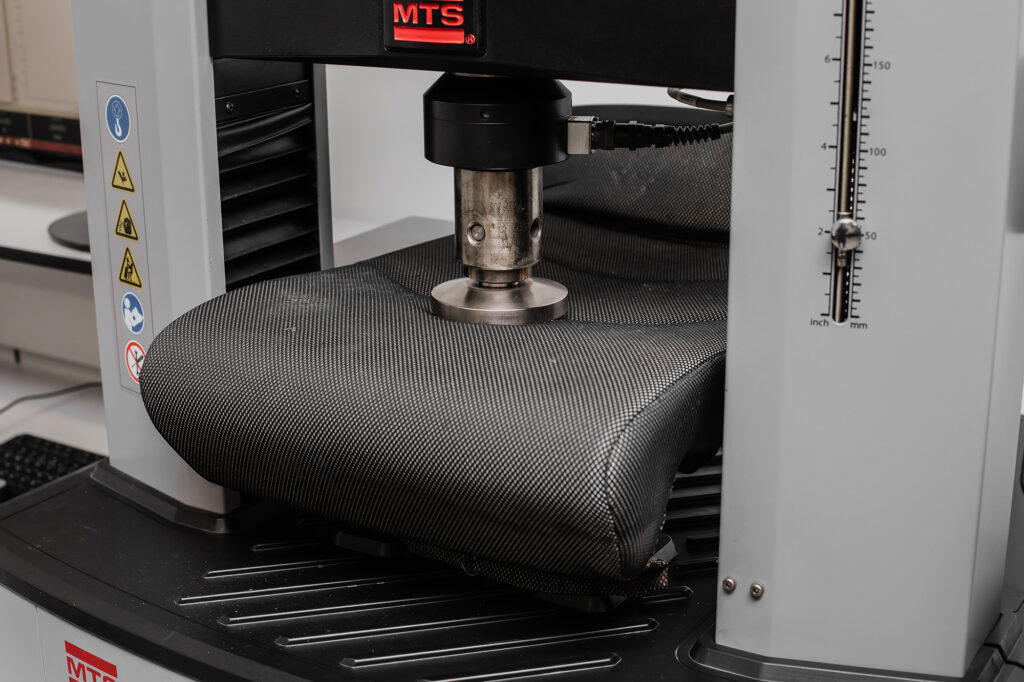

MTS Criterion Model 43 Electromechanical Universal Test Systems

A static tensile, compression and bend testing machine with computer recording of force and elongation measurements. The machine is also equipped with a range of grips and ends for clamping specimens of various shapes.

We perform tests according to the testing standards specified by the customer or based on individual customer requests. We design test paths for non-standard requirements.

Parameters:

- 0-30 kN measuring range

- Accuracy of force indication 1 N

- diameter dimensions for round specimens 3-12.7 mm

- maximum dimensions for flat specimens :

Width: 25mm | Thickness: 13.2mm | Length: 500mm

We conduct tests on:

- plastics

- metals

- textiles

- rubbers

- wires

- ropes

- fasteners

- threaded connections,

- metal-rubber components.

DIC and microDIC digital image correlation system

Digital image correlation is a technique for measuring displacements and deformations in real time. The results are presented in the form of colour displacement and deformation maps, making it possible to verify the formulated numerical models. The measurements not only provide static images, but also the possibility of visualising the deformation process in the animation form. In addition to measuring the values of the parameters under investigation, this makes it possible to analyse the deformation process itself, including the observation of fracture processes, crack propagation and the destruction of various materials and structures.

System allows for:

- measurement of displacements with an accuracy of 1 µm,

- precise determination of mechanical parameters such as Young’s modulus E, Poisson’s number,

- determination of selected mechanical parameters for different areas of the specimen during one strength test

MTS Acumen dynamic system

MTS Acumen dynamic system is a testing machine for dynamic and static testing of materials and structures.

Parameters:

- Maximum load 12 kN,

- Spindle dynamics 100 Hz,

- Vertical test space from 30 mm to 600 mm,

- Dynamic spindle feed 70 mm (+/- 35 mm)

Thermal chamber

Thermal chamber is used for determining the mechanical properties of materials and structures at elevated and reduced temperatures.

Temperature range – 35°C to 300°C

Four-camera digital image correlation system

Digital image correlation is a technique for measuring displacements and deformations in real time. The results are presented in the form of colour displacement and deformation maps, making it possible to verify the formulated numerical models.

The measurements not only provide static images, but also the possibility of visualising the deformation process in the form of animations. This gives, in addition to measurements of the values of the parameters under investigation, the possibility to analyse the deformation process itself including the observation of fracture processes, crack propagation and failure of various materials and structures.

Technical data:

- measurement of displacements with an accuracy of 1 µm,

- precise determination of mechanical parameters such as Young’s modulus E, Poisson’s number,

- determination of selected mechanical parameters for different areas of the specimen during one strength test.

Station for the preparation of samples and non-standardised test procedures

Haas Mini Mill CNC

CNC Mini Mill – a full-featured small parts processing unit.

Movement ranges:

- Oś X – 406 mm

- Oś Y – 305 mm

- Oś Z – 254 mm

Table:

- Length – 914 mm

- Length of workspace – 730 mm

- Width – 305 mm

Universal lathe with readout for 2 axes

Parameters:

- Turning diameter over bed – 360 mm

- Turning diameter over slide – 224 mm

- Turning diameter over bridge – 491 mm

- Turning length – 1000 mm

- Spindle speed range – 90 – 2000 rpm

- Maximum tool size – 16 x 16 mm

- Longitudinal feed range – 0.078 – 1.044 mm/rev

- Transverse feed range – 0.018 – 0.238 mm/rev

- Metric thread – 0.45 – 10 mm

- Inch thread – 2.25 – 40 T.P.I.

- Tailstock sleeve diameter – 32 mm

OPTIMUM DP 33 table drill

Parameters:

- Drilling diameter in steel (S235JR): 30 mm

- Drilling diameter in steel – continuous (S235JR): 25 mm

- Working table length: 355 mmm

- Number of T-slots: 2

- Working table width: 355 mm

- Work table rotation: 360 °

- Work table inclination: 45 °

- T-slot size: 14 mm

- Distance between spindle and drilling table: 784 mm

- Speed range: 120-1810 rpm

- Number of speed ranges: 9

Lincoln POWERTEC I250C semi-automatic welding machine

Technical data:

- Welding current range [A] :10-250

- Current [A] – cycle : 250A@60%; 195A@100%

- Additional functions : 2/4 cycle, arc control, MMA welding, flux-cored wire welding