The laboratory is dedicated to a wide range of R&D activities in support of modern dentistry and prosthetics. It is designed to enable the creation, research and development of innovative solutions to different types of dental challenges, including the process of diagnosis, design and creation of personalised prosthetic models: crowns, bridges, implant abutments, skeletal prostheses, etc.

By equipping the laboratory with the latest computer technology, including CAD/CAM, as well as hardware – a magnetic milling machine – we support dentists and prosthodontists involved in digital prosthetics in Poland, as well as those who are just implementing these standards.

Our equipment and technology offer great opportunities for extremely beneficial and efficient collaboration in the field of prosthetic component manufacture. Thanks to the CNC milling machine, we are able to manufacture a full range of products in titanium, chrome cobalt, zirconium, glass-ceramic and many other materials on the basis of an imported digital STL file (image of the prosthetic base or designed shape of the future prosthetic product).

We carry out material tests under conditions that simulate dynamic changes in the physical conditions of the dental system, covering all groups of metallic, ceramic, polymeric and composite materials.

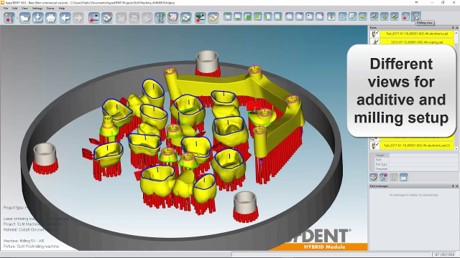

RS5 magnetic milling machine with CAM software

- 3 + 2 milling including such materials such as: zircon, titanium, CoCr

- intended for the manufacture of prosthetic products such as: implants, acrylic dentures, surgical guides and glass–ceramic products with trochoidal machining

- software containing a package of implant geometries and implant connectors

SD Mechatronik THE-1100 Thermocycler

A thermocycler equipped with an open specinem basket that is alternately immersed in a bath of hot and cold liquid to provide a high rate of temperature change (to realistically simulate temperature changes in the oral cavity), thereby simulating the artificial ageing process of materials used for prosthetic restorations.

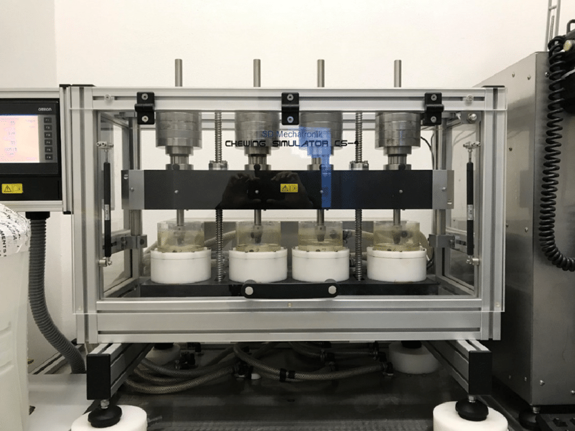

SD Mechatronik CS-4 chewing movements simulator

The unit simulates various chewing movements in the mouth to evaluate materials used for implants, bridges, crowns, composites and jaw models:

- complete chewing cycles with 2-axis linear movement

- 2-axis circular motion for higher simulation frequencies up to 5Hz

- simulation of bruxism, in particular for the testing of splints