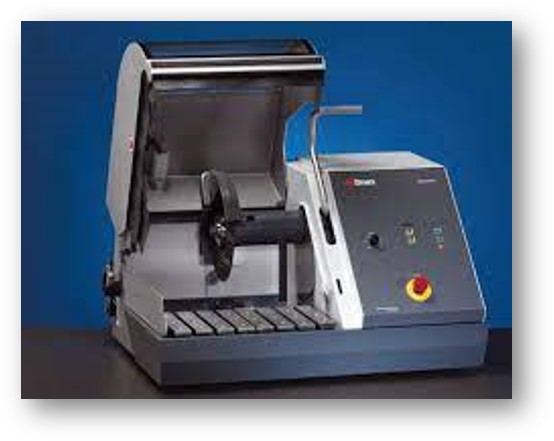

Discotom 6 - an universal cutting machine

Discotom-10 cutting machine

A universal high precision cutting machine with automatic table feed in X and Y axes.

- VarioSpeed (Discotom-100) – the cut-off wheel speed can be adjusted from 1.500 to 3.000 rpm to optimise for material hardness and application.

- OptiFeed – ensures the correct feed speed without compromising cut quality or wheel economy.

- AxioWash – automatic cleaning programme to clean the inside of the machine.

- ExciCut – speeds up manual cutting of very hard materials.

- Method Database – store up to 20 cutting methods for easy recall.

- Cut-off wheel database – All Struers cut-off wheels are stored with recommended speed and

thickness.

Secotom-15 - a high-precision cutting machine

High performance table top cut-off machines with moving cutting table and variable speed. Motorized workpiece positioning and digital display. OptiFeed function.

Technical specifications:

- Intelligent feed control (OptiFeed) that automatically reduces the feed speed to an appropriate value

- Cutting wheel diameter from 75 to 200 mm

- Variable cut-off wheel speed from 300 rpm to 5000 rpm in 100 rpm increments.

- Cutting capacity 165 x 50 mm or bars up to 70 mm with a maximum cutting length of 190 mm

- Height adjustment of the cut-off wheel in a range of 40 mm

- Manual X-stand with digital display, positioning accuracy of 5 μm.

- Recirculating cooling unit

Citopress-30

An advanced, electro-hydraulic, programmable, twin-cylinder assembly press. The CitoPress-30 offers total process control, database facilities, and synchronous or independent operation of both cylinders. For thermal encapsulation of samples: max. d = 38 mm

LaboPol-60 – a manual grinding/polishing machine

A variable speed grinding/polishing machine (50-500 rpm) for two 250 or 300 mm diameter discs. Each disc with automatic water valve, manual splash guard, and pad. One LaboForce-50/-100 specimen mover can be fitted.

Tegramin-30 – an automatic grinding/polishing machine

Automatic, microprocessor controlled machine for grinding and polishing samles on a 300 mm conical MD-Disc with dosing modules and specimen holders.

LectroPol-5 – polishing and electrolytic etching equipment

A fully automatic, microprocessor controlled electrolytic polishing and etching unit. Complete with control unit, polishing unit, and external etching unit with one set of masks and two electrolyte containers.

Lavamin – ultrasonic sample cleaner

Specimen cleaning unit for cleaning of specimen holders up to 160 mm dia. and for individual specimens in specimen mover plates for Tegramin-25, -30, TegraForce-5, and RotoForce-4. Levelling unit, retention rings in 25 mm / 1.0″, 30 mm / 1.0″, 40 mm / 1.0″, and 50 mm / 2.0″ dia., and rubber mats are included.

Kromas/VRM 2 – a vibratory finishing machines

Kromas vibratory finishing machines are versatile, flexible and efficient machines.

Vibratory finishing machines are used for finishing of metal, plastic, ceramic, stone, glass, wood and rubber products. Vibratory finishing processes include: deburring, rounding, polishing, descaling, deflashing, degreasing, cleaning, smoothing etc.