Microscope examination station:

Leica DMi8 microscope

Objectives: 5 x, 10 x, 20 x, 50 x, 100 x

Ocular: 10 x

Microscope in an inverted configuration allowing observation of metallographic samples together with a high-resolution digital camera. Fully automated microscope allowing software and touch panel control, as well as automatic XYZ axis image folding.

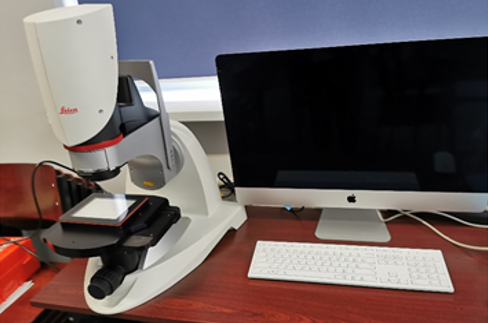

Leica DM750M microscope

Objectives: 5 x, 10 x, 20 x, 50 x

Ocular: 10 x

Metallographic microscope for observing metallographic samples together with a high-resolution digital camera.

- possibility to observe samples in reflected and transmitted light for brightfield, side illumination and polarisation techniques

- possibility of data recording on SD card

- possibility to control the camera operation and image capture by another workstation via WiFi communication

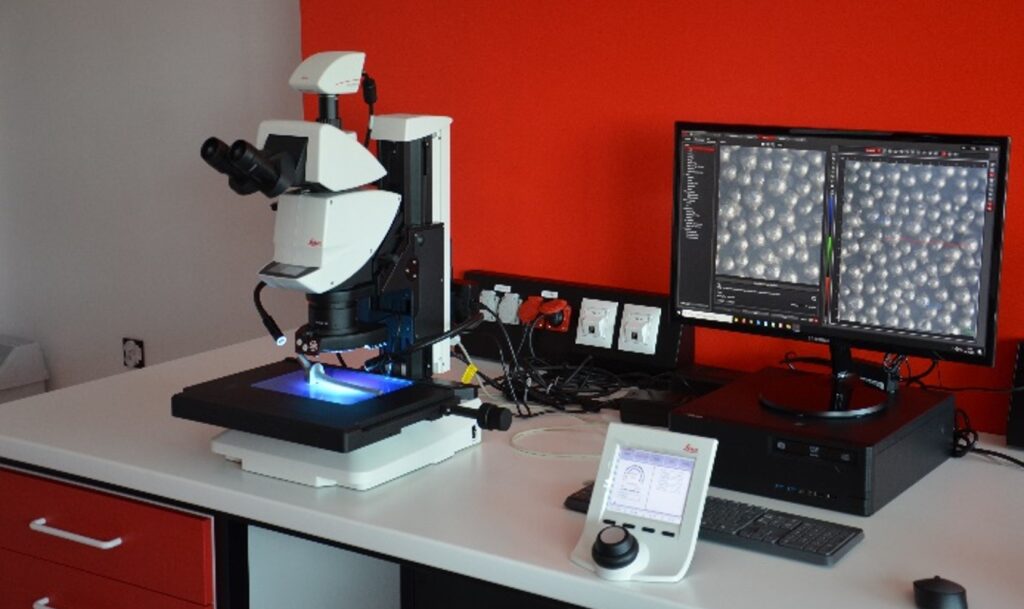

Modular stereo microscope Leica M205 A

Magnification range: 7.8 x – 160 x (1.0 x objective, 10 x eyepiece)

Parameters:

- a software module allowing measurement of parameters such as area (circle, square, rectangle and any shape), radius, diameter, angles and generation of reports from these measurements as an Excel file

- a software module enabling the generation, visualisation and measurement of 3D surfaces derived from the scanning of an image with extended depth of field in the z-axis.

Leica S9i stereo microscope

Magnification range: 7.8 x – 160 x (1.0 x objective, 10 x eyepiece)

- manual tripod in the z-axis

- computer and software integration

- software module enabling measurement of parameters

- such as area (circle, square, rectangle and any shape), radius, diameter, angles.

Digital microscope Leica DVM6 A

3 objectives (with magnification range from 12 x to 2350 x)

For real-time inspection, with image capture, video recording and measurement capabilities. Fully automated microscope allowing control from software and automatic image assembly in XYZ axes – creating 3D maps of the surface.

The system is equipped with:

- tilting head (from -60° to +60°),

- width of field of view: 43.75 mm, 12.55 mm, 3.6 mm

- illumination in transmitted and reflected light

- fully motorised table and all-in-one PC with LAS X software for 2D and 3D analysis

- motorised axial movement with manual focusing.

Test stations for surface topography, wetting angle and surface free energy:

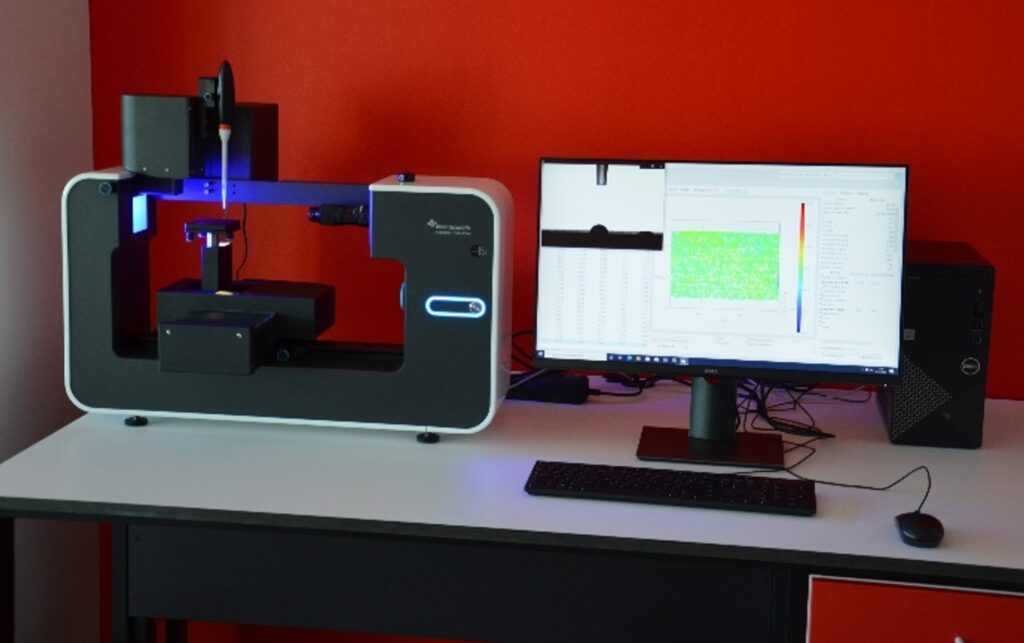

Optical tensiometer with Theta 3D topography system

Measuring ranges:

- wetting angle: 0-180°, accuracy ±0.1°,

- Surface/interphase tension: 0.01 – 1000 mN/m, accuracy ±0.01 mN/m.

- Integrated topographic module for 2D and 3D surface imaging with option to take into account the correction of surface irregularities on the wetting angle;

- automated wetting angle testing exactly on the surface with the determined topographic characteristics.

Parameter analysis according to ISO 4287, ISO 4288:

- r (Wenzel equation)

- ϴc, wetting angle with roughness correction/Wenzel

- wetting angle

- Sdr (%), Sa (um), Sq (um)

- Horizontal and vertical parameters for any 2D line from the graph Ra, Rq,Rp, Rv, Rz, R10z

Imaging options:

- Optical image, 2D and 3D roughness map:

- Maximum sample dimensions on the table: unlimited x 180 mm x 22 mm (L x W x H).